We provide a full range of 3D metrology applications that are all intended to deliver accurate measurements and analysis for a variety of sectors. The many demands of companies looking for precision, effectiveness, and dependability in their metrology procedures are satisfied by these one-stop solutions.

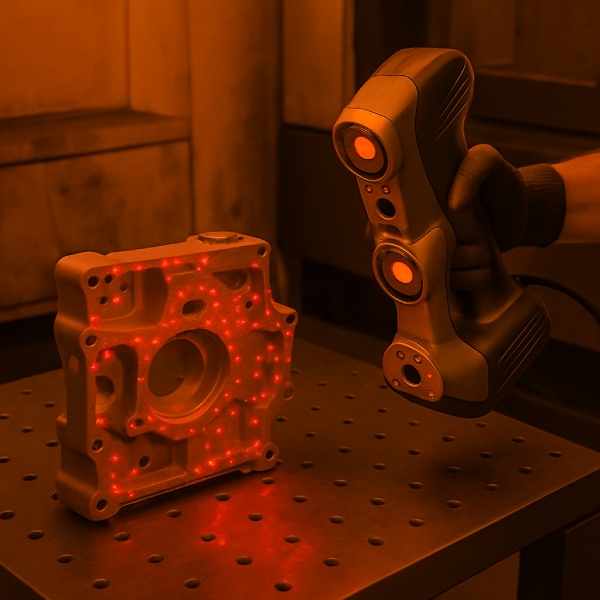

Component Scanning & Quality Inspection

This process involves 3D scanning and detailed analysis of manufactured components to ensure they meet dimensional and quality standards. It helps detect defects, deviations, and inconsistencies in early production stages. The data collected is used to validate part geometry and improve product reliability.

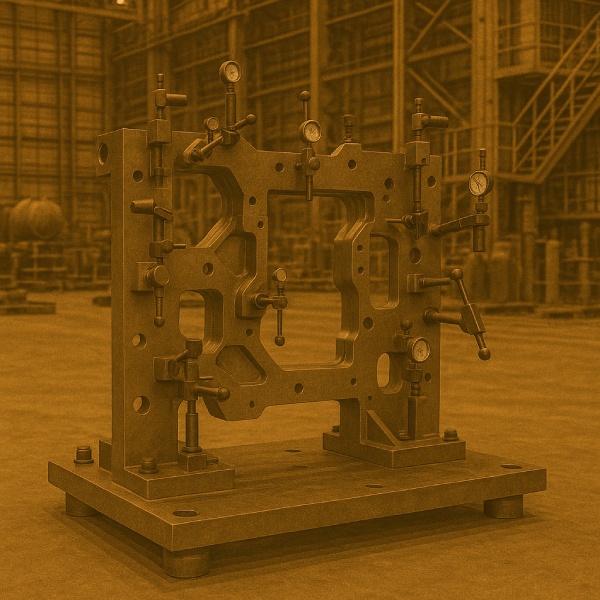

Tool Building & Certification (Jigs, Fixture validation)

Involves inspection and validation of tools such as jigs and fixtures used in manufacturing. It ensures tools are built to design specifications and can accurately position or hold parts during production. Certification confirms their readiness for use in critical operations, reducing errors and improving efficiency.

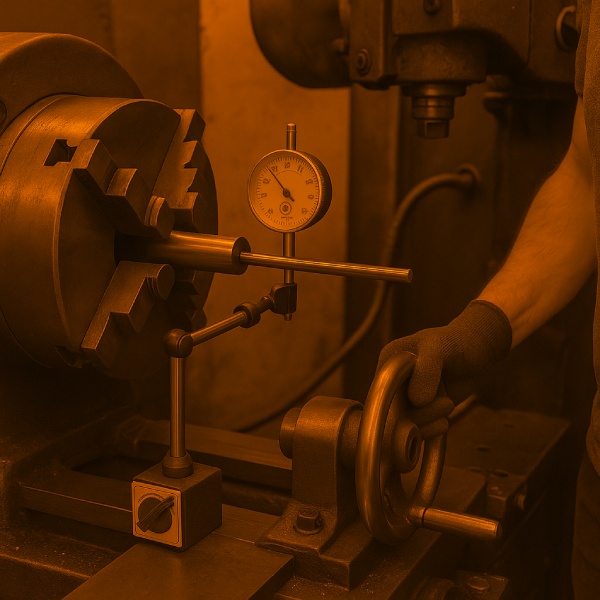

Machine Alignment (Periodic Maintenance of current Machines)

Regular alignment checks are essential for maintaining the precision of machines such as CNCs or assembly lines. Misalignment can cause wear, reduced output quality, and machine damage. This application helps extend machine life and maintain consistent performance.

Metal Fabrication: WARPAGE Detection, First Article Inspection, Periodic Part Inspection

Metal parts are inspected for warpage, deformations, and overall dimensional accuracy. First Article Inspections (FAI) verify that initial samples meet all required specifications before mass production. Periodic inspections ensure ongoing quality and help identify process deviations early.

Molding / Tool & Die: Mold & Die Inspection

This includes the evaluation of molds and dies used in casting or molding processes. Accurate inspection ensures the tools produce parts within tight tolerances. It prevents defects in the final product and ensures long tool life through proper maintenance and adjustments.

CAD model-based inspection on the surface, CAD profile-based inspection

Manufactured parts are compared directly to their CAD models for both surface and profile accuracy. 3D scanning or touch-probe systems detect deviations from design intent. This method is vital for ensuring high-precision components in industries like aerospace and automotive.

GD&T inspection of large components / Assembly

Geometric Dimensioning and Tolerancing (GD&T) ensures parts fit and function together as intended. This inspection evaluates features like flatness, concentricity, and parallelism. Especially important for large assemblies, it guarantees proper alignment and mechanical compatibility.

Calibration of CNC / CMM machines and Robots

Calibration ensures machines like CNCs, CMMs (Coordinate Measuring Machines), and robots deliver precise movements and accurate measurements. It involves adjusting machine settings to match known standards. Regular calibration minimizes operational errors and maintains production accuracy.

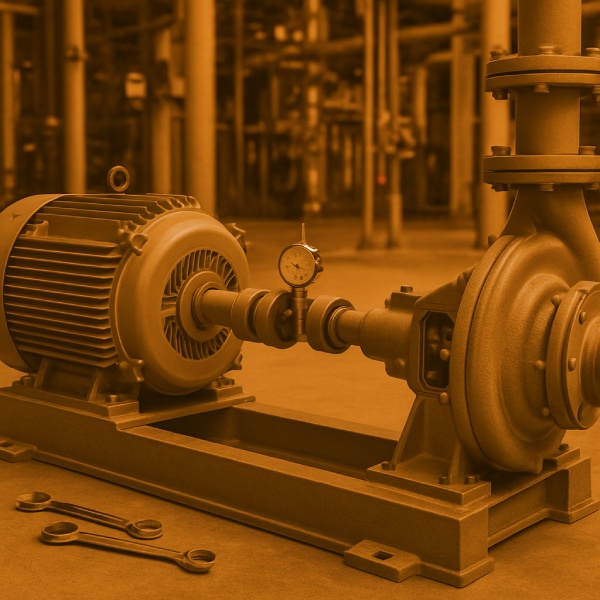

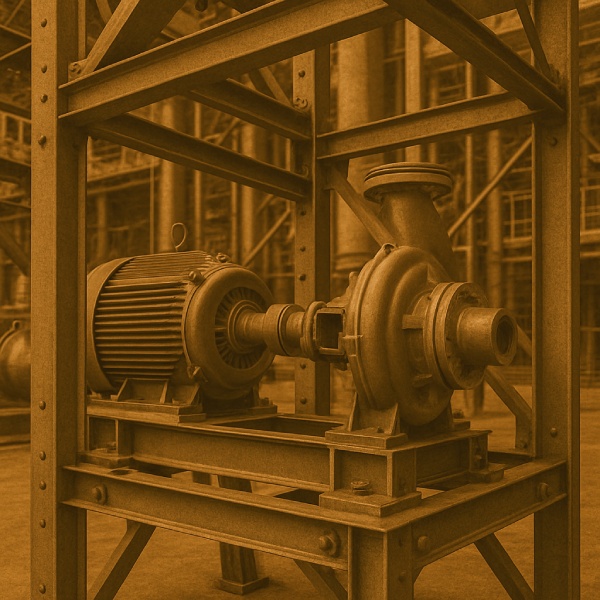

Alignment and Installation of Machineries

Precise alignment and installation ensure machines operate efficiently and safely. Misaligned equipment can lead to excessive wear, energy loss, and unexpected breakdowns. Advanced tools like laser alignment systems are used for accurate setup. This process helps extend the equipment’s lifespan and minimizes maintenance downtime.

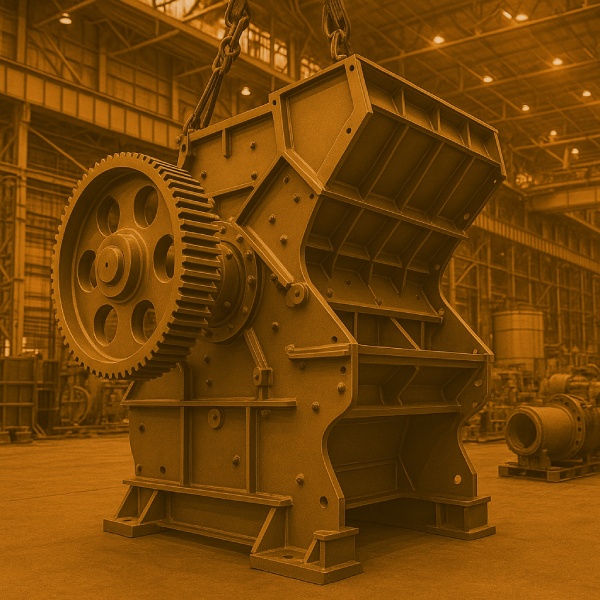

Large Machine Building

Large machine building involves assembling heavy-duty industrial equipment with high precision. The process includes structural welding, fitting, and geometric validation. Advanced metrology techniques are used to verify dimensional tolerances. Ensuring accuracy at each step is essential for reliable machine performance.

Equipment Fixing in the Structure

Fixing equipment in structural frameworks requires accurate positioning to maintain stability and function. It involves anchoring, alignment, and level checks using laser levels or alignment tools. Proper fixing prevents vibration, wear, and operational faults. It is especially critical in large installations or multi-component systems.

JIG & Fixture Building as well as Inspection

Jigs and fixtures must be built to exact tolerances to ensure repeatable machining or assembly. Their inspection involves checking dimensional accuracy and stability. Metrology tools like CMMs and laser scanners are used for verification. Quality jigs/fixtures improve productivity, consistency, and worker safety.

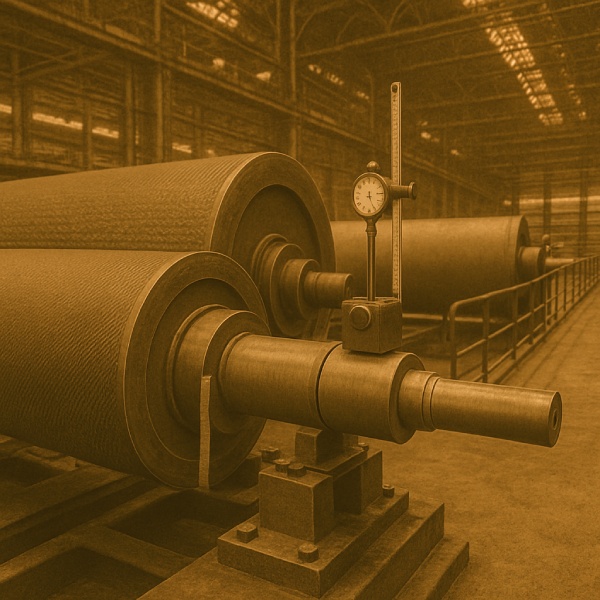

Roller Alignments (Steel Plant, Paper Mill & Sugar Mill)

Roller alignment is crucial for continuous processing industries like steel, paper, and sugar mills. Misaligned rollers can cause product defects, uneven tension, and equipment damage. Laser alignment tools are used to ensure rollers are parallel and correctly spaced. Proper alignment improves production efficiency and reduces wear.

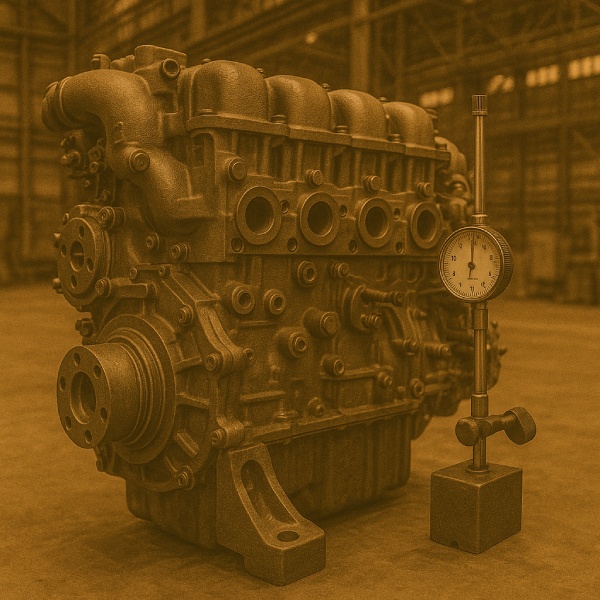

Engine Mount Inspection

This involves checking the alignment and integrity of engine mounts in machinery or vehicles. Misaligned mounts can lead to vibrations, noise, and mechanical damage. Techniques like 3D scanning or dial gauge measurements are used. Regular inspection ensures performance and prevents premature wear or failure.

Symmetry Check

Symmetry checking verifies whether components or assemblies are balanced and uniformly shaped. It’s critical in parts like turbine blades, shafts, or housings. Laser measurement or 3D scanning is used for high-precision comparison against design specifications. Ensuring symmetry improves mechanical balance and reduces failure risks.

Machinery Position (Operational Check)

This application verifies the positional accuracy of machinery during or after operation. It ensures the equipment is operating within the expected geometric and spatial tolerances. Tools like laser trackers and encoders are often used. This helps detect shifts, misalignments, or structural deformations over time.

Industries We Serve

Aerospace / Defense

Architecture & Construction

Automotive / Sheet Metal & Pattern Making

Casting & Forging

Heavy Engineering

Heritage

Medical Device Manufacturing

Oil & Gas

Public Safety

Pumps & Valves

Ship Building